Sample Simulation: TiO Particle Formation

The FPM is used to simulate particle formation and growth in

chemical reactors, such as TiO2 particles, according to the

following process:

The production of gas-phase TiO2 is simulated with FLUENT, and the

production of TiO2 particles is simulated with the FPM.

.

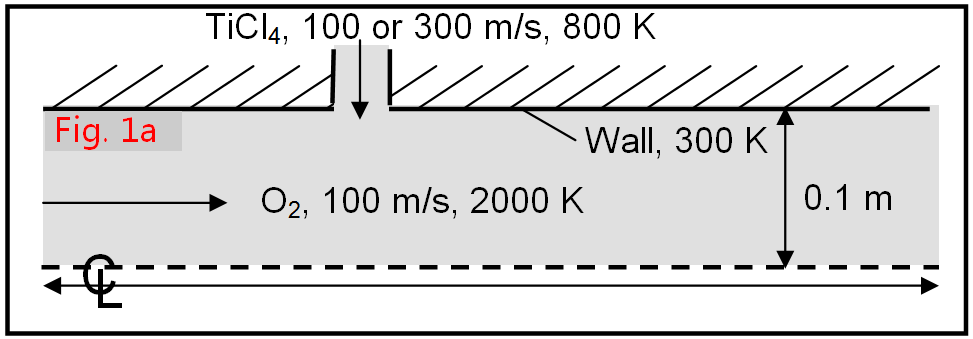

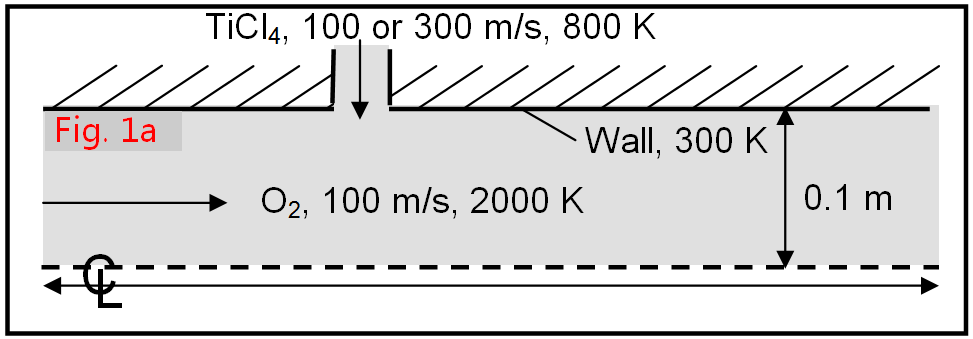

The FPM can be used to simulate the effect of reactor geometry and

operating conditions on the formation of particles. For the reactor

geometry and operating conditions shown in Fig. 1a, and for a given mass

flowrate of TiCl4, the FPM can be used, for example, to simulate the effect

of the velocity of the TiCl4 inlet stream on the radial uniformity of particle

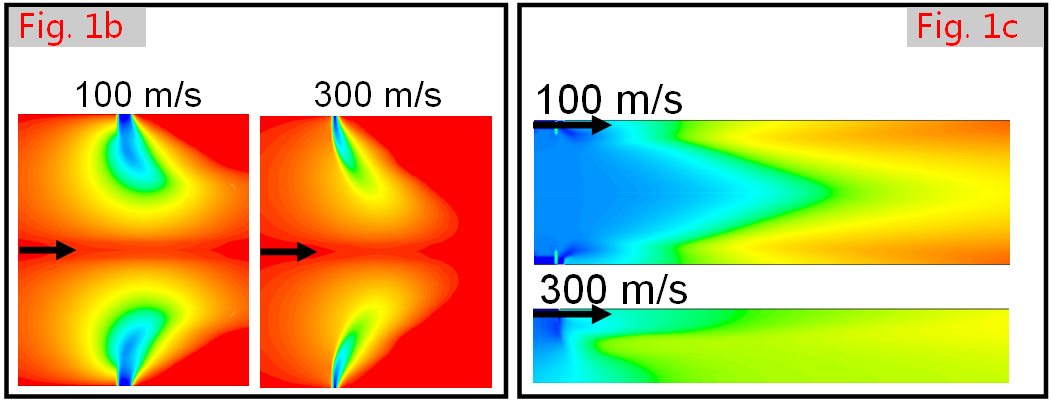

size. Figure 1b shows radial velocity contours for TiCl4 inlet velocities of

100 and 300 m/s, where blue and red indicate the maximum

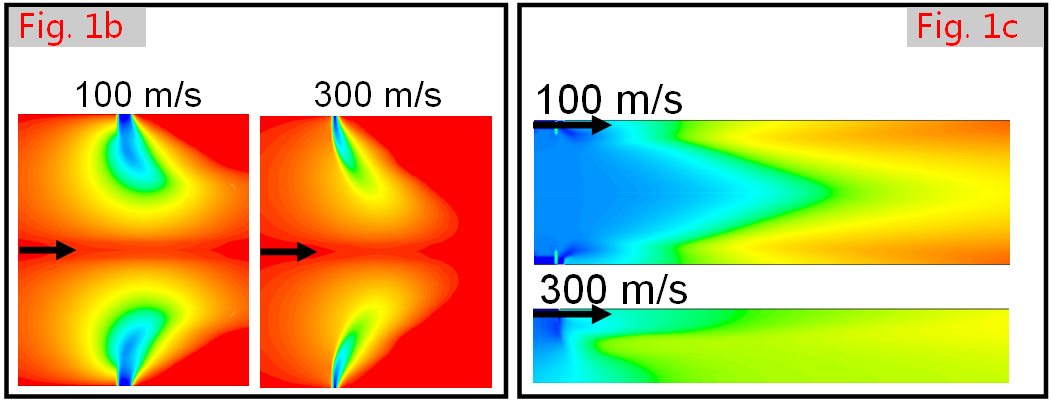

and minimum radial velocities, respectively. Figure 1c shows contours of

diameter, where blue and red represent minimum and maximum particle

diameters, respectively. Figure 1c shows that the radial distribution of

particle diameter is more uniform for the TiCl4 inlet velocity of 300 m/s

than for 100 m/s. The FPM can also be used to calculate the distribution of

particle number and mass.

Copyright 2021. All rights reserved.

Chimera Technologies, Inc.

15051 Zodiac St. NE

Forest Lake, MN , USA 55025

Tel: 1-651-464-7771

Email: info@cfd.com